Integrated process and measurement technology for the highest demands

Centec develops and manufactures fully automated, frame-mounted process plants and high-precision measurement technology from a single source. This integrated product range is virtually unparalleled in its breadth and depth. Our systems and sensors are specifically designed to meet the demanding requirements of the brewing, beverage, food, and pharmaceutical industries. A team of experienced brewmasters and engineers ensures that every solution sustainably improves the efficiency and profitability of our customers' processes – from planning and design to commissioning.

Line Performance

Standardized skids, short downtimes, optimized CIP cycles.

Quality in the process

Inline measurement of °Brix, O₂, CO₂, temperature, conductivity.

automation

Recipe-controlled, batch management, traceability, interfaces to MES/ERP.

Service & Training

Remote support, spare parts concepts, training, performance audits.

Turnkey Beverage: Process Lines & Utilities

Turnkey solutions for breweries and beverage production: water, syrup room, mixing, carbonation, CIP, utilities. Goal: reproducible quality, high OEE, fast changeover times.

Stainless steel process tanks and containers for storage, mixing and buffering – individually manufactured, hygienically designed and optimally integrated into the plant process.

Scope of services Beverage

Engineering: P&ID, 3D layout, media concept, utility balances

Syrup room, mixing/blending, carbonation, degassing, dosing

Water treatment, filtration, mineralization/demineralization

CIP/SIP systems, tanks, valve blocks, hygienic piping

Inline analysis: °Brix, CO₂, O₂, turbidity, temperature, conductivity

Automation: PLC/SCADA, recipes, batches, audit trail

Documentation & FAT/SAT, training, handover to production

Integration: Filler/Labeler/Packaging, Line Coordination

1. Concept

Product portfolio, volumes, quality targets, OEE drivers, layout.

2. Engineering

P&ID, 3D, valve matrix, CIP concept, automation, schedule.

3. Manufacturing & FAT

Skids pre-assembled, functional and leak tests, formulations.

4. Installation & SAT

Hook-up, media, line coordination, SAT, ramp-up plan.

5. Qualification

Process fine-tuning, quality approvals, OEE fine-tuning.

6. Lifecycle

Maintenance, spare parts strategy, training, performance audits.

Process solutions

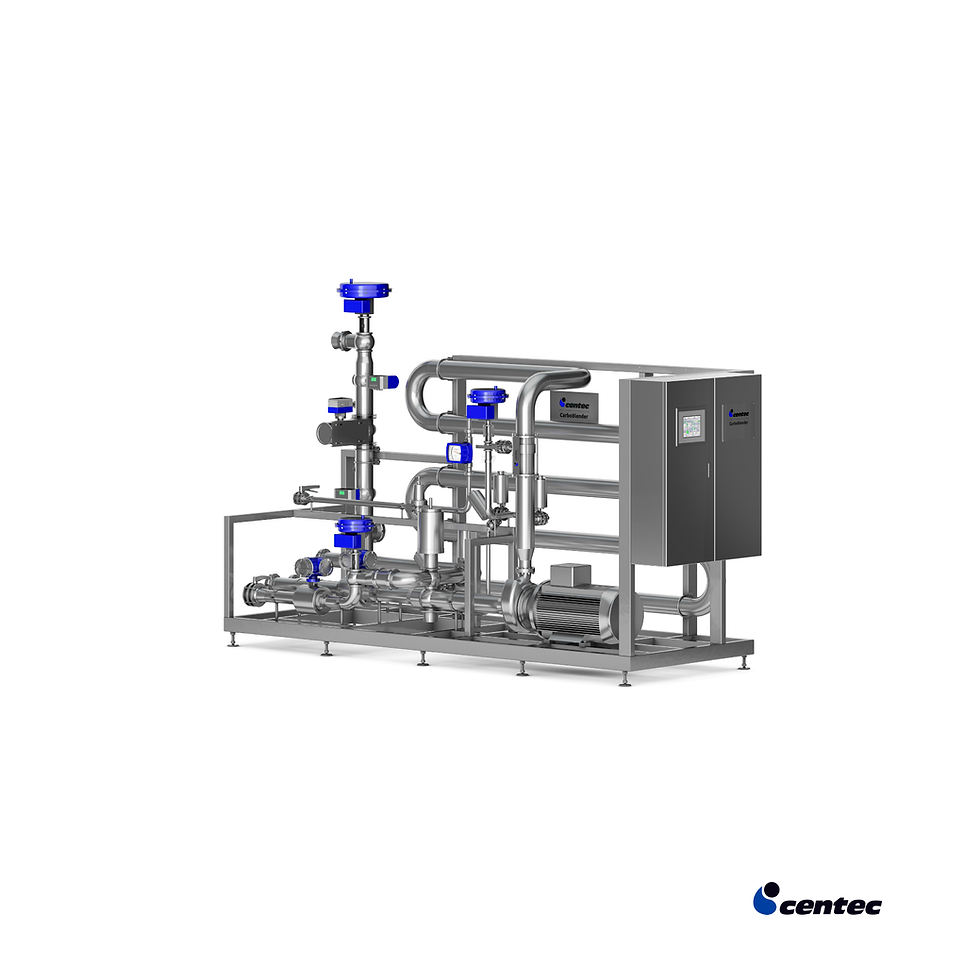

Modular skids – from craft to large breweries

Our pre-assembled, frame-mounted systems with integrated measuring technology offer maximum flexibility. They are scalable, energy-efficient, and hygienically designed – individually planned, precisely manufactured, and perfectly tailored to your production processes.

Sensors

Measurements you can rely on

Robust, hygienic in-line measurement – developed for the requirements of breweries. All devices are low-maintenance, easy to clean, and designed for integration into existing control systems (e.g., PLC/SCADA).

Proven at leading breweries

Centec solutions are used worldwide – from the craft segment to high-volume lines.

Examples: DeGaS cold systems, high-gravity blending, dosing and carbonation modules.

CONTACT

Do you have questions or a specific project?